Tips & Tricks

Philips screws on Bearing holders

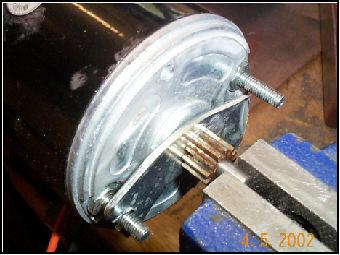

Keying the metal gear on to the motor

spindle

Drawing by RoR |

On other homepages I have seen that people are breaking a lot of drills trying to lock the gear wheel. |

I decided to do a part of the process in reverse order.

|

First I cut of the motor spindle as describe in chapter 6. Then I "glued" the metal gears on to the motor spindle with Locktite 601. |

Photo by RoR |

| Then I set up a fixture in the pillar drill using a drill vice to hold the motor and clamp to lock the position of the gear & motor spindle. |

|

|

I started drilling with a center drill, because it is more robust than a ordinary drill. After drilling a millimeter or two changed to a 1.5 mm HS drill, and used a small drop of cooling fluid. |

|

|

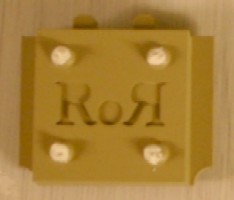

Philips screws on Bearing holders The bearing holders are made up from a sandwich of 4 layers of steal bolted together with 3mm screws 6 nyloc nuts. As philips screws are not seen on railroad trucks in real life I decide to cover the holes before the final painting. |

|

|

|

|

Bearing holders assembly with acrylic sealant covering the holes |

Acrylic sealant is cut away | After painting it looks as if it had been riverted. |